- Company: McGuire and Hester

- Industry: General Building

- Location: San Carlos, California

- Expected Completion Date: November 14, 2014

- Project Website

Palo Alto Medical Foundation’s San Carlos Center is a state-of–the-art, full service medical center. McGuire and Hester began work in 2009 in the preconstruction phase and later as a Trade Partner for Lean Project Delivery with Skanska USA Building, NBBJ, and Palo Alto Medical Foundation. This project was one of the first true Integrated Project Delivery (IPD) projects on the west coast. IPD is a project delivery approach that integrates people, systems, business structures and practices into a process that collaboratively harnesses the talents and insights of all participants to optimize project results, increase value to the owner, reduce waste, and maximize efficiency.

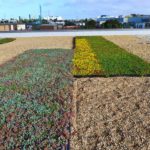

Leading the site work for this new 18.1-acre medical facility, McGuire and Hester broke ground in March of 2012 with the mass excavation for the Medical clinic and parking garage. Following the rough grade operation, we moved to domestic utilities, asphalt paving, installation of integral concrete flat work and tunnel walls, and green roof installation

What impact does this project have on America?

PAMF Medical Center – San Carlos campus fully integrates ambulatory care, acute care and common space to provide a new level of patient-focused care for San Carlos and surrounding communities. The urgent care center will be open every day, 365 days a year, from 7 a.m. to 9 p.m.

Projects such as this state of the art medical center give Americans an alternative to visiting ERs, keeping patients out of hospitals both to improve the quality of care and to help keep costs under control.

What interesting obstacles or unusual circumstances did you overcome to complete the project?

After working in the preconstruction phase in 2009 the project was put on hold due to funding, toxic soil and concerns over traffic congestion. The delays postponed the groundbreaking for nearly three years, however due to the LEAN methods and IPD model that the project followed, team collaboration and excellent communication before and after the project broke ground kept it successful.

What dangers and risks did you encounter, and describe any extraordinary methods used to keep workers safe?

At an integrated project delivery (IPD) job site team members are required to make dependable promises and speak directly about safety concerns. Trade Partners are required to have field personnel attend Safety Meetings to discuss any safety items. The project has created a PSLT (Project Safety Leadership Team) to address any issues from these meetings. This direct communication boldly addresses topics that hinder a safe job site. The collaborative work environment, paired with daily pre-task planning, safety meetings, and stretch and flex breaks led to an excellent safe environment.

In May of 2013, McGuire and Hester was invited to the FIRST Skanska Safety Banquet in Northern California where we were honored with the IFE (Injury Free Environment) Partner / Subcontractor Support Award. This award is given to those who have exemplified the Skanska IFE environment, safety principles, and quality by going above and beyond in their performance.

How did you leverage new technologies to work faster and reduce waste?

The project used integrated project delivery to complete the project more quickly and efficiently than traditional construction methods. Integrated project delivery, which emphasizes heavy collaboration among project stakeholders, and it also extensively used lean construction practices which greatly reduced the project’s carbon footprint. Having the project’s key stakeholders – including the client, Skanska, the designers, McGuire and Hester, and trade partners – operate out of a common Big Room office accelerated and improved decision making.