- Company: Miller Bros. Const., Inc.

- Industry: Transportation

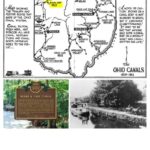

- Location: Napoleon, Ohio

- Expected Completion Date: June 25, 2015

- Project Website

The ODOT Stone Arch Project included rehabilitation of eight stone arch culverts originally built in the mid-1800s as part of the Miami & Eire Canal. Miller Bros. setup and maintained cofferdams and bypass flume pipes at eight separate locations to allow access to the work area(s), and they removed and reconstructed the existing stone block headwalls and wingwalls. They replaced damaged stone blocks with limestone replacement blocks or precast concrete blocks and installed wire mechanically stabilized earth walls behind the reconstructed block headwalls and wingwalls to relieve earth pressure from the newly reconstructed block walls. Some locations required temporary excavation shoring due to the close proximity of existing roads and/or structures. This was done with soil nails and a reinforced shotcrete wall. Temporary shotcrete wall heights varied from 10 feet to 30 feet.

What impact does this project have on America?

This project shows that old and new construction technologies can be used in concert to replace/repair our transportation assets at the same time preserving the craftsmanship and aesthetics that were used over 150 years ago. Some locations we were required to replace damaged stone blocks with in-kind limestone blocks and other locations we used pre-cast concrete. The finish and color of the pre-cast blocks were to be as close as possible to limestone to help blend in with the existing blocks. Given these were originally part of the Miami & Erie Canal, we are also preserving a part of Ohio’s history for future generations.

What interesting obstacles or unusual circumstances did you overcome to complete the project?

At location S4 HEN-424-10.78, the existing 20-foot span by 10-foot rise by 128-foot-long stone arch culvert was to be removed and reconstructed. The plans showed the culvert sitting on a 3-foot-thick pad of rubble. When the area was dewatered it was discovered that the culvert was actually sitting on wooden timbers. After several months of waiting on direction from Ohio Department of Transportation, it was decided to leave the arch blocks in place and re-line the inside the culvert with a corrugated metal multi-plate arch on a cast-in-place concrete spread footer cast on top of the existing timbers. With a several month delay and a few flood events this location was finally completed in 2014.

What dangers and risks did you encounter, and describe any extraordinary methods used to keep workers safe?

The culverts were 200’ to 1000’ of the Maumee River so one of the big risks of this project was high water and flood events. When the Maumee River water level went up so did the water in the creeks where the stone culverts are located. Although it did not pose a worker safety issue it did pose an equipment and material issue and it took some planning to make sure if there was a potential high water event we had everything up and out of the work area and on high ground.

How did you leverage new technologies to work faster and reduce waste?

The original excavation/temporary bracing shown in the plans included soldier pile and wood lagging walls and sheeting. These sites did not have a lot of room to work due to limited right-of-way so we opted to go with a soil nail & shotcrete wall system which also saved time and money.Cofferdams were required at all of the locations to dewater the work areas. Our original plan was to use sand bags & stone to construct the dams, but given the water depth it was difficult to get a good seal and maintain a dry work area. So we decided to try the Portadam System for all the locations. These were much more efficient system for our work areas. Not only the installation time, but also if the site was flooded the repair of the dams was very quick and we were back to work.